PSB Globe ValvesCast Stainless Steel Pressure Seal Bonnet

■ Basic design : ASME B16.34, API 623, BS1873, Intergral seat type

■ Flange drilling : ANSI B16.5

■ Face to face : ANSI B16.10

■ Test : API 598

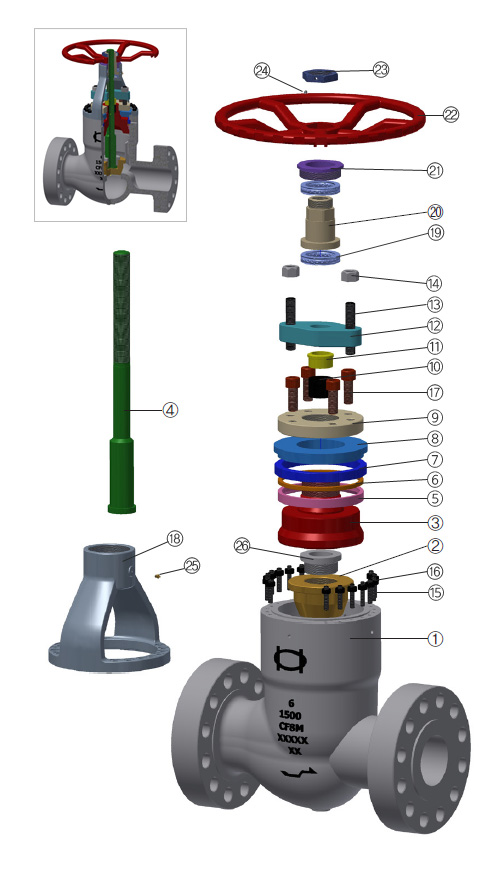

① BODY The body of the high pressure globe valve is designed as an one piece casting, with smooth inside contour providing maximum flow efficiency.

The body has an integral casting guiding system to guide the disc full throught the valve stroke.

The pressure seal type globe valve is designed with 4 holes in the neck at the region of the segment ring for a proper disassembly.

The contacting surface the pressure seal gasket outside has a stainless steel 18-8 inlay to assure soundness and corrosion resistance for carbon and alloy steel valves.

② DISC The disc contacting surface with deposit stellite no.6 hard facing is ensured by pressure tightness and freedom from sticking.

It is connected to the stem by means of a lock nut.

Special attention is given to the seating face which are ground and lapped to a perfectly tight seal.

③ BONNET The bonnet is designed and manufactured in order to ensure a perfect seal, as well as to allow for easy dismounting and reassembly.

A longer packing life is ensured by a condensation chamber inserted between the backseat and the packing.

④ STEM The non-rotating or rotating rising stem has trapezoidal thread.

The stem is ground to minimize friction and prevent damage to gland packing.

The stem is jointed to the disc by means of a lock nut.

The stemhead has a tapered shoulder for backseating purpose.

⑳ YOKE SLEEVE The yoke sleeve is made from cast austenitic ductile iron having high resistance to wear and a high melting point.

It is designed to permit removal from the bonnet or the yoke while the valve is in service.

■ Flange drilling : ANSI B16.5

■ Face to face : ANSI B16.10

■ Test : API 598

① BODY The body of the high pressure globe valve is designed as an one piece casting, with smooth inside contour providing maximum flow efficiency.

The body has an integral casting guiding system to guide the disc full throught the valve stroke.

The pressure seal type globe valve is designed with 4 holes in the neck at the region of the segment ring for a proper disassembly.

The contacting surface the pressure seal gasket outside has a stainless steel 18-8 inlay to assure soundness and corrosion resistance for carbon and alloy steel valves.

② DISC The disc contacting surface with deposit stellite no.6 hard facing is ensured by pressure tightness and freedom from sticking.

It is connected to the stem by means of a lock nut.

Special attention is given to the seating face which are ground and lapped to a perfectly tight seal.

③ BONNET The bonnet is designed and manufactured in order to ensure a perfect seal, as well as to allow for easy dismounting and reassembly.

A longer packing life is ensured by a condensation chamber inserted between the backseat and the packing.

④ STEM The non-rotating or rotating rising stem has trapezoidal thread.

The stem is ground to minimize friction and prevent damage to gland packing.

The stem is jointed to the disc by means of a lock nut.

The stemhead has a tapered shoulder for backseating purpose.

⑳ YOKE SLEEVE The yoke sleeve is made from cast austenitic ductile iron having high resistance to wear and a high melting point.

It is designed to permit removal from the bonnet or the yoke while the valve is in service.

※ If you do not see it all, drag the table to the left or right.

| No | Name of Part | ASTM specification | |||

|---|---|---|---|---|---|

| Cast Stainless steel | |||||

| 1 | BODY | A351 CF8 | A351 CF3 | A351 CF8M | A351 CF3M |

| 2 | DISC | A351 CF8 | A351 CF3 | A351 CF8M | A351 CF3M |

| 3 | BONNET | A351 CF8 | A351 CF3 | A351 CF8M | A351 CF3M |

| 4 | STEM | A276 304 | A276 304L | A276 316 | A276 316L |

| 5 | PRESSURE SEAL | A240 304 / GRAPHITE + 304 | A240 304L / GRAPHITE + 304L | A240 316 / GRAPHITE + 316 | A240 316L / GRAPHITE + 316L |

| 6 | SPACER RING | A351 CF8 / A240 304 | A351 CF3 / A240 304L | A351 CF8M / A240 316 | A351 CF3M / A240 316L |

| 7 | SEGMENT RING | A351 CF8 / A240 304 | A351 CF3 / A240 304L | A351 CF8M / A240 316 | A351 CF3M / A240 316L |

| 8 | BONNET RETAINER | A351 CF8 / A240 304 | A351 CF8 / A240 304 | A351 CF8 / A240 304 | A351 CF8 / A240 304 |

| 9 | GLAND PLATE | A351 CF8 / A240 304 | A351 CF8 / A240 304 | A351 CF8 / A240 304 | A351 CF8 / A240 304 |

| 10 | PACKING | TEADIT / PILLAR | TEADIT / PILLAR | TEADIT / PILLAR | TEADIT / PILLAR |

| 11 | GLAND RING | A276 304 | A276 304L | A276 316 | A276 316L |

| 12 | GLAND FLANGE | A351 CF8 / A276 304 | A351 CF8 / A276 304 | A351 CF8 / A276 304 | A351 CF8 / A276 304 |

| 13 | GLAND FLANGE BOLTS | A194 B8 | A194 B8 | A194 B8 | A194 B8 |

| 14 | GLAND FLANGE NUTS | A194 8 | A194 8 | A194 8 | A194 8 |

| 15 | YOKE BOLTS | A194 B8 | A194 B8 | A194 B8 | A194 B8 |

| 16 | YOKE NUTS | A194 B8 | A194 B8 | A194 B8 | A194 B8 |

| 17 | DRAW BOLTS | A194 B8 | A194 B8 | A194 B8 | A194 B8 |

| 18 | YOKE | A351 CF8 | A351 CF8 | A351 CF8 | A351 CF8 |

| 19 | BEARING | 52100 | 52100 | 52100 | 52100 |

| 20 | YOKE SLEEVE | A439 D2C | A439 D2C | A439 D2C | A439 D2C |

| 21 | SLEEVE NUT | A276 304 | A276 304 | A276 304 | A276 304 |

| 22 | HANDLE WHEEL | A536 60 | A536 60 | A536 60 | A536 60 |

| 23 | HANDLE NUT | A194 8 | A194 8 | A194 8 | A194 8 |

| 24 | SET BOLT | A194 B8 | A194 B8 | A194 B8 | A194 B8 |

| 25 | GREASE NIPPLE | A307 B | A307 B | A307 B | A307 B |

| 26 | DISC NUT | A276 304 | A276 304L | A276 316 | A276 316L |

※ Note. - Packing & pressure seal material ; customer's requirements